PRODUCTS

Roll Bow Designs, Manufactures and Refurbishes its Curved Rolls always with the purpose of improving the Quality and Productivity of operation. Thus, its curved rollers eliminate wrinkles, folds, centers or loose ends; Restores the Threading on Screens; It improves the performance of the Felts; Expands the sheet evenly at the Entrance of the Dryers; Prevents shrinkage in drying Avoiding wrinkles; Preserves the uniform tension of the sheet before the Coater and Eliminates wrinkles resulting from moistening; Provides a coil without wrinkles and firm.

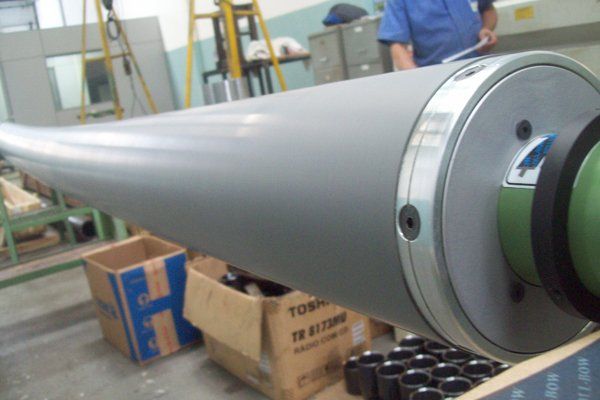

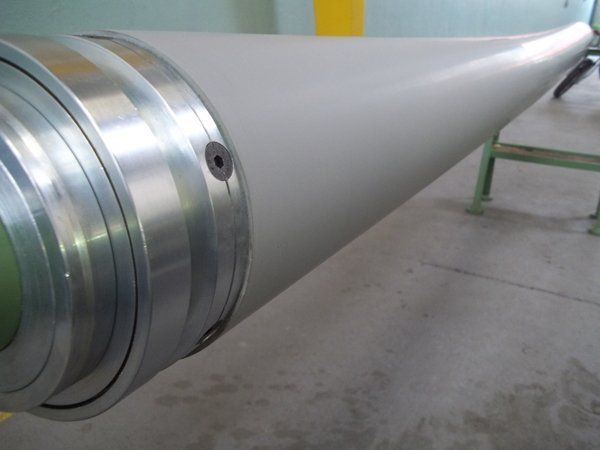

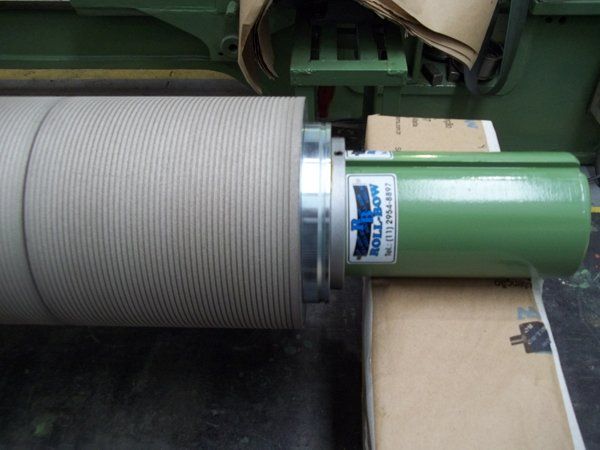

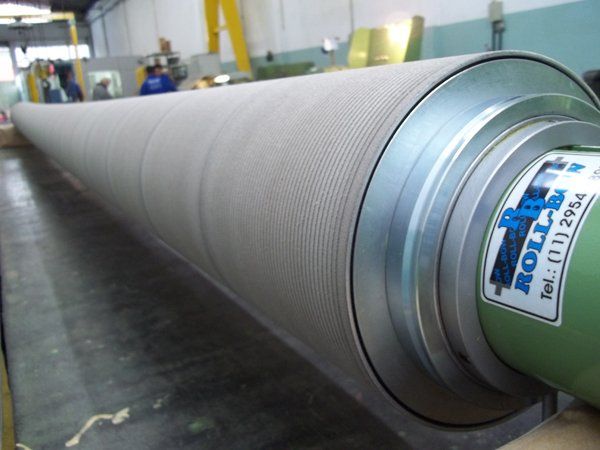

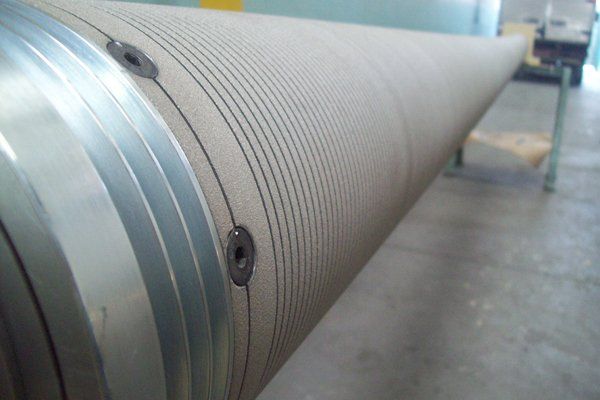

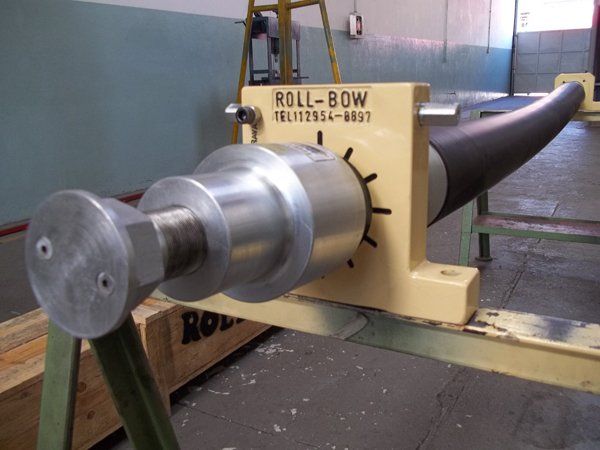

CURVED ROLLERS COATED IN SMOOTH OR SLOT RUBBER:

They are indicated to work in all positions of the machine. Being suitable to operate in wet and humid environments - Press, Felt, Size Press, Speed Size, Coater, others - Supplied also in Grooved Rubber operating in a dry environment, at high speed - Winder, Rewinder

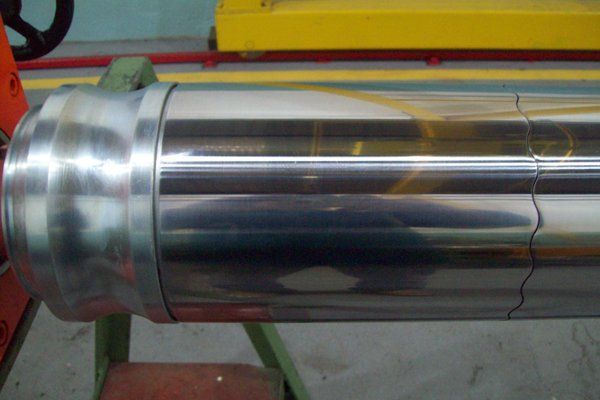

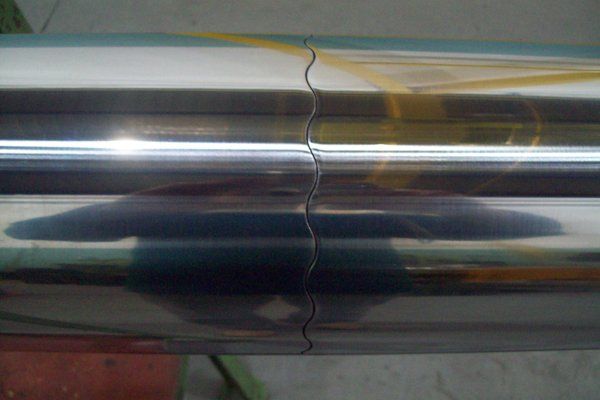

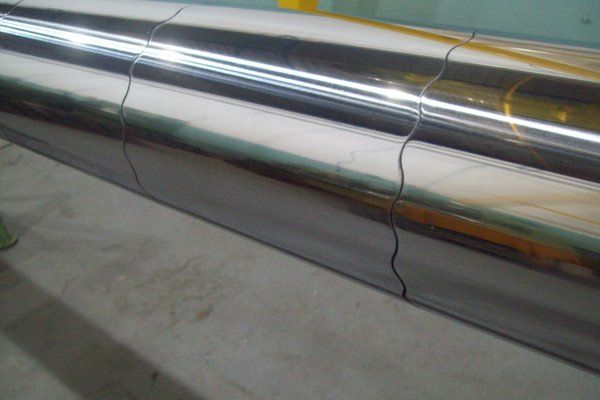

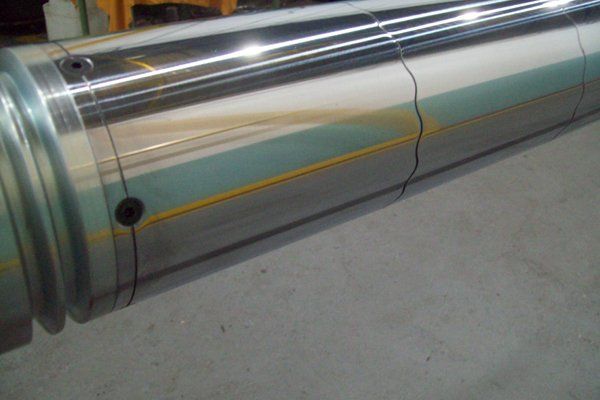

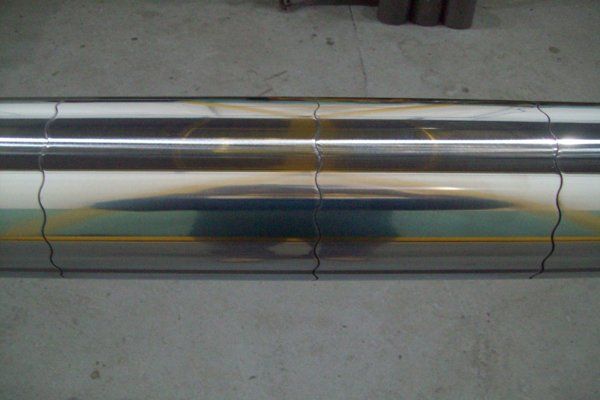

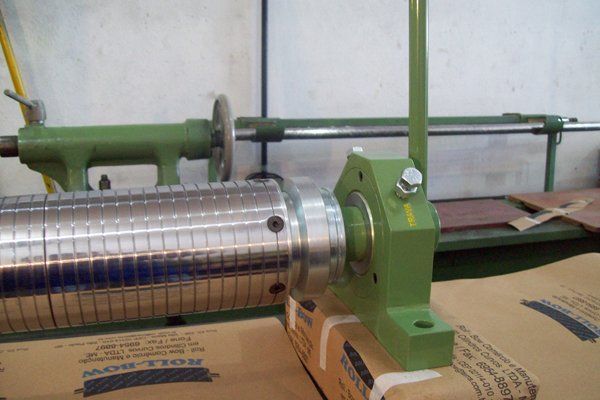

SENOIDAL METALLIC CURVED ROLLS:

For Wet and Aggressive Applications, due to High Temperatures, such as Infrared, we offer the Sinusoidal Metallic Curved Roller Coated in Polished Hard Chrome. Even with the wet material, its formation in sine waves prevents marking on the sheet, as well as providing longer durabiand performance - Drying, Post-Drying

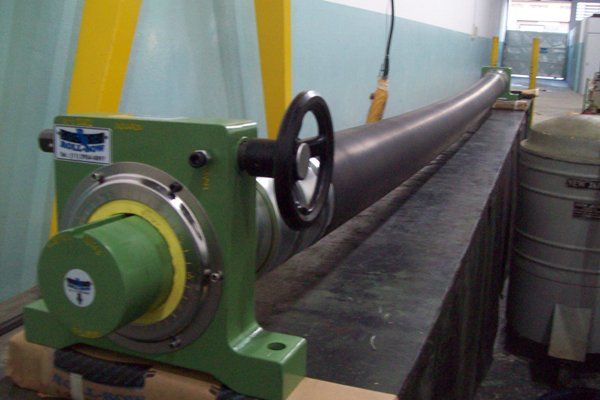

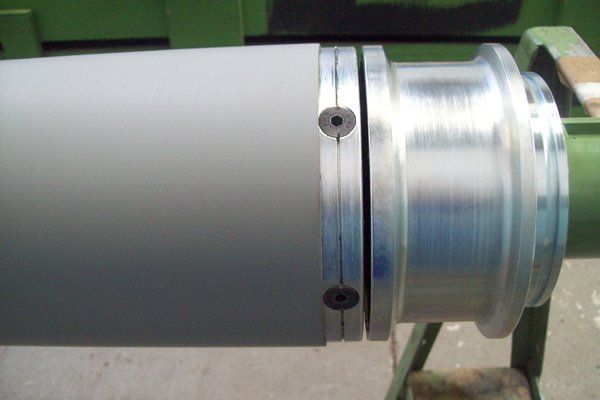

CURVED ROLLER WITH VARIABLE CURVATURE - MECHANICAL:

The Curved Roller with Adjustable Curvature Coated in Smooth or Grooved Rubber, Smooth Metallic or Grooved in Polished Hard or Matte Chrome or Metal Spray, allows the curve to be defined and adjusted in the field Mechanically by the machine operator himself. It is indicated to work with different types of materials in different weights, moisture content and various cuts Rewinder, Size Press

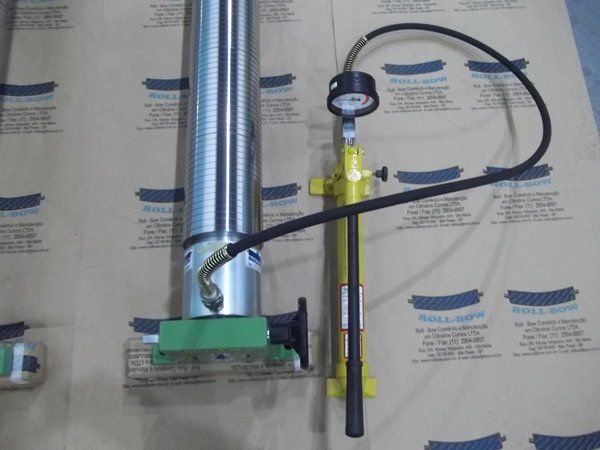

CURVED ROLLER WITH VARIABLE CURVATURE - HYDRAULIC:

The Curve of this Cylinder is defined and adjusted in the field by the machine's operator through a Hydraulic Pump. ROLL BOW Provides Curved Rolls with Adjustable Curvature Coated in Smooth or Grooved Rubber, Smooth Metallic or Grooved in Polished Hard or Matte Chrome or Metal Spray. Suitable for working with various types of materials in varying weights, moisture content and various cuts - Rewinder, Size Press

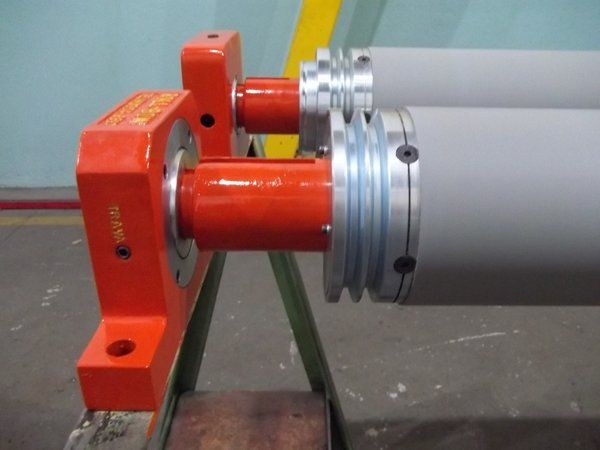

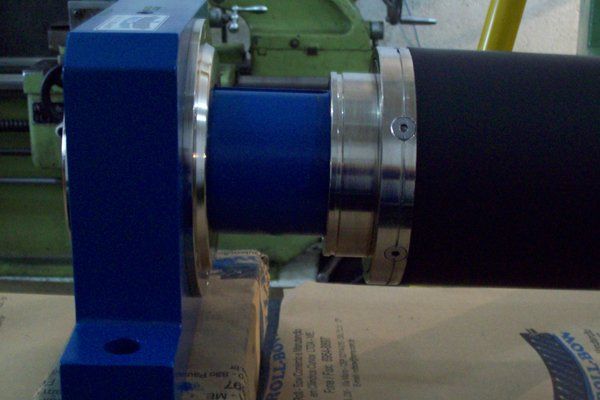

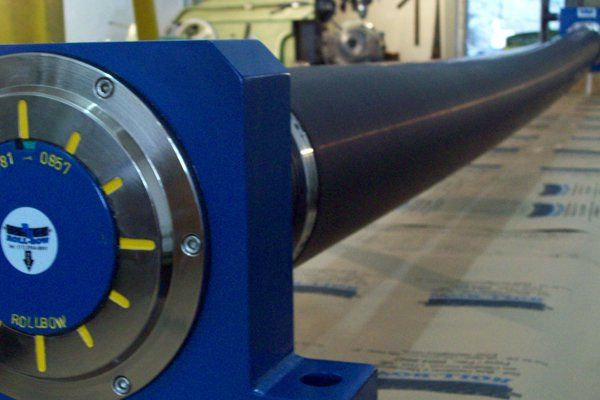

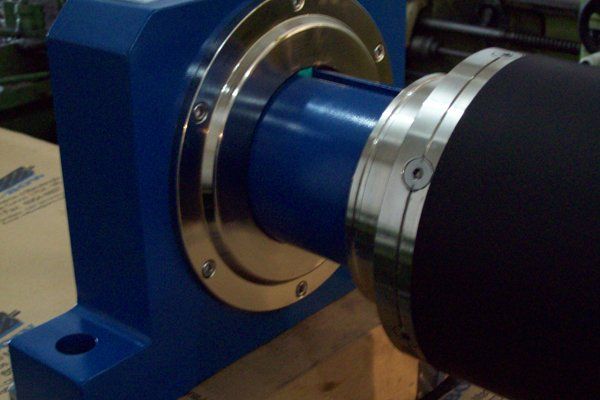

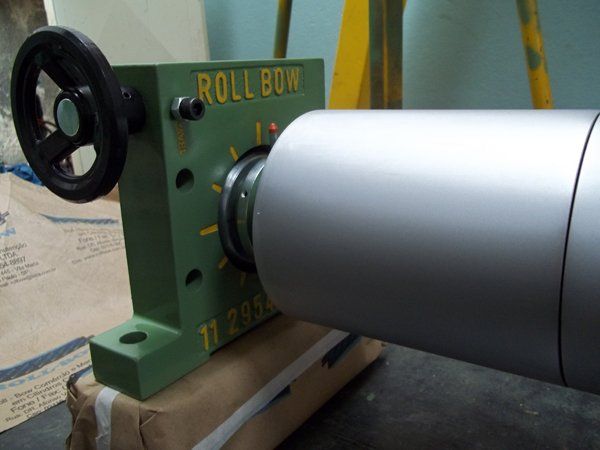

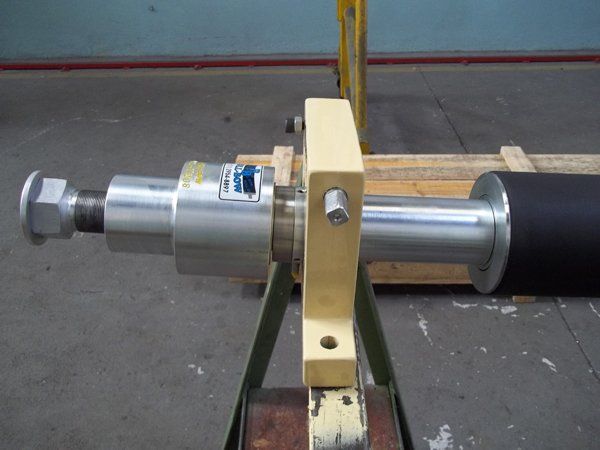

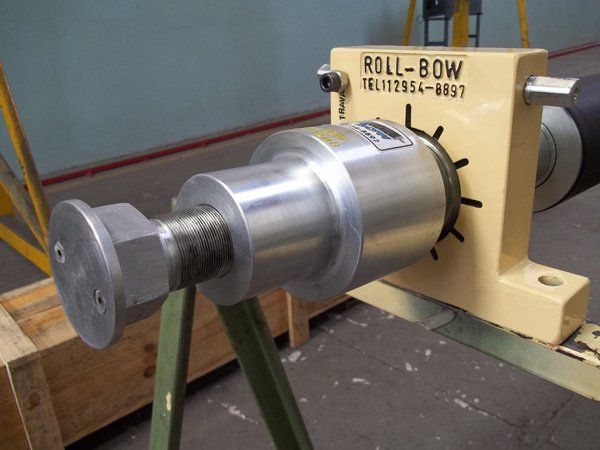

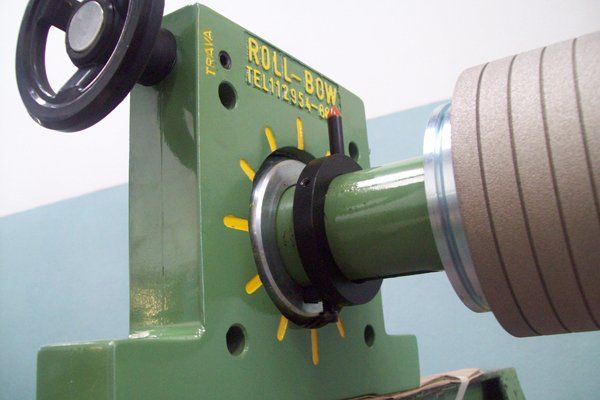

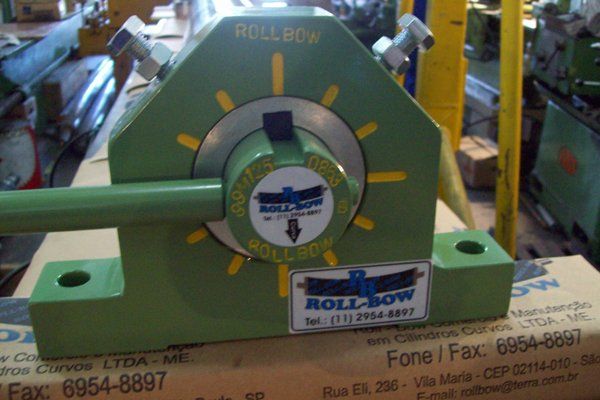

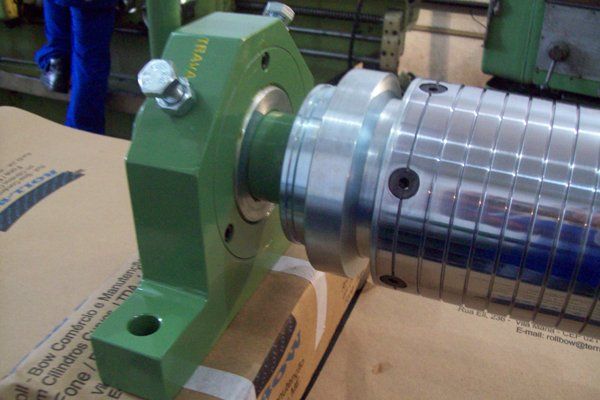

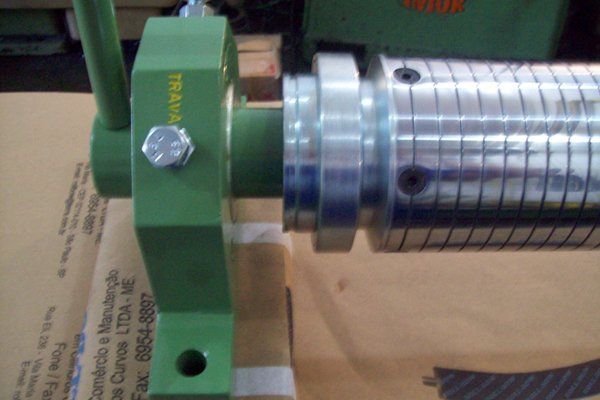

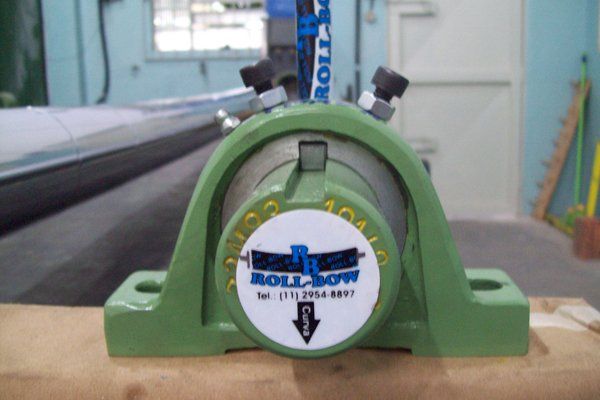

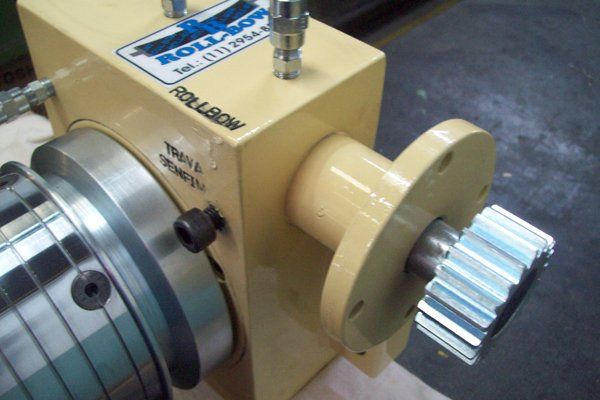

ROTARY BEARINGS

Supplied with a Drilling System that allows the Fixation on the Machine both by the Columns - Flanged Drilling - as by the Bases - Drilling on the Bearing Bases - The Rotating Bearings guarantee a Comb-fine adjustment in the positioning of the Curved Roller Curvature thanks to the Crown and Worm with Axial Bearings that give greater lightness to the handling of the Positioning Bearing. Supplied with Graduated Ring - Clock, Steering Wheel and Ferrule accompanies the Arrows fixed on the Axis Points giving Direction to the Curve Direction of the Cylinder.

STANDARD BEARINGS

The Curvature of the Curved Roller is Positioned through the Axis with the Assistance of a Lever connected to its Tip. Also supplied with a Tip that accompanies the Arrows fixed on the Points of the Axis giving Direction to the Direction of the Bend. Supplied with Flange Drilling or Base Drilling.

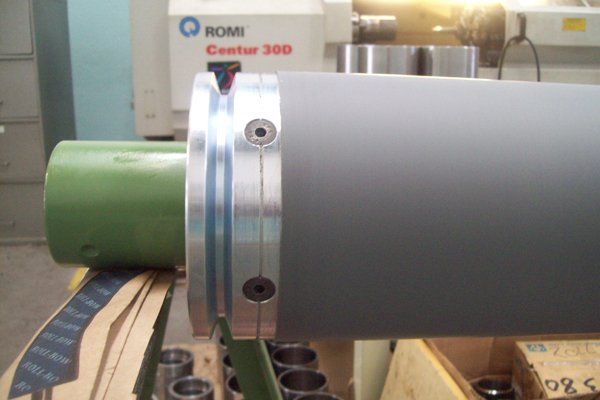

SPECIAL BEARINGS:

Roll Bow supplies Exclusive Bearings, according to the configuration of each Machine. With data provided by the Client, we develop each Bearing through the elaboration of Drawing / Sample / Sketch. After approval by the Technical Staff of the Machine, we proceed to the Manufacture of the Bearings that will satisfy, to the extent, the unique need of each user.

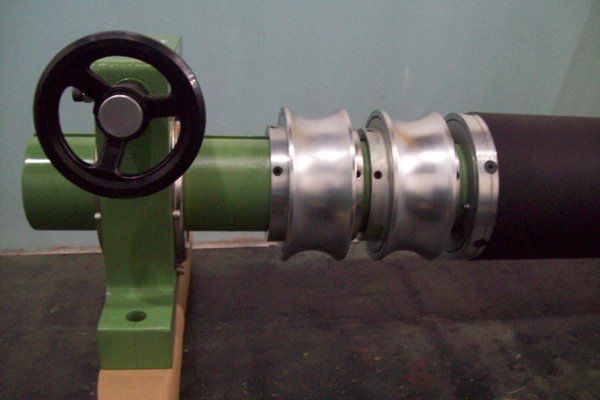

PULLEYS:

According to the needs of each Client, Roll Bow supplies its Curved Rollers with or without Pulleys.

Drive Pulleys - Through Belts / Ropes - this Pulley drives the Curved Roller.

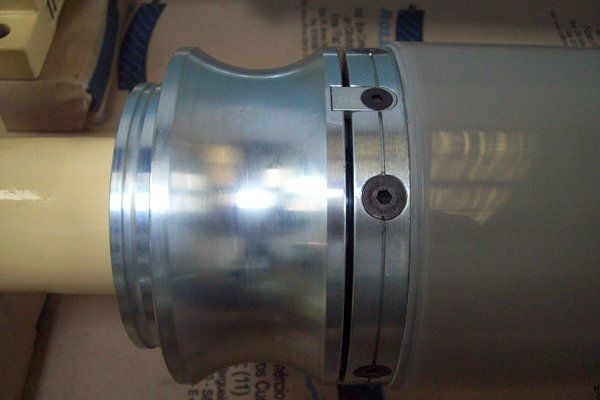

Rope Pass Pulleys - Crazy Pulley Guide-Rope - Works independently of the Curved Cylinder. Can be supplied with Double System - Crazy or Fixed. Through Latches / Keys we can leave it Fixed - Working Together with the Curved Cylinder - Driven Pulley - or make it Crazy - Working Independently, Rotating Independent of the Curved Roller.

THE Roll Bow, for Interchangeable Positions, provides or adapts when Reforming, Curved Rollers with Crazy Pulley Guide-Rope Mobile or Double Pulley, also Mobile. Thus, the same Curved Roller can work in more than one Position on the Machine, since the Mobility of the Pulleys allows the adjustment of the same with the position of the Rope.